E 70HD

The heavy-duty, powerful and energy-efficient production lathe with optimum accessibility in the WEILER E-Series range

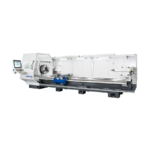

The allrounder for high productivity applications with a high chip removal rate for turning lengths up to 6 metres and spindle bores up to 216 mm.

A smart range of optional features ensure a high level of efficiency for turning through to milling operations.

Precise and universally usable, it impresses through:

- State-of-the-art control and drive technology

- Straight-forward operating and programming

- Extreme accuracy

- Durability

- User-friendly ergonomics

- and an extensive range of accessories.

- Distance between centres 1.000 mm – 6.000 mm

- Swing over bed 720 mm

- Speed range of 1 to 1800 rpm

- Main drive with power of 37 kW

- Spindle bore 128 mm or 165 / 216 mm

- Maximum torque 3400 Nm

- Display unit with 22″ Touchscreen

- Ingenious, user-friendly WEILER graphical user interface

- Operating panel with handwheels moves with the bed slide to enable precise manual machining

- “e-TIM” energy conservation system minimizes power consumption

- LED machine lights

- Increased machine accuracy to DIN 8605

| WORKING RANGE | |

| Centre height | 360 mm |

| Swing over bed | 720 mm |

| Swing over cross slide | 430 mm |

| Distance between centres | 1.000 – 6.000 mm |

| LATHE SPINDLE | |

| Spindle nose acc. to DIN 55027 (DIN ISO 702-3) | size 11 |

| Spindle bore | 128 mm* |

| Spindle diameter in front bearing | 180 mm |

| MAIN DRIVE | |

| Drive power 60% / 100% duty cycle | 37/30 kW |

| Speed range | 1 – 1.800 min-1 |

| Number of speeds | stepless |

| FEED RANGE | |

| Number of feeds | stepless |

| Feed force longitudinal | 0,001 – 50 mm/turn |

| Feed force transverse | 0,001 – 50 mm/turn |

| Feed force longitudinal | 25.000 N |

| Feed force transverse | 13.000 N |

| Max. Feed range longitudinal and transverse | 10/5 m/min |

| THREAD CUTTING RANGE | |

| Metric threads | 0,1 – 2.000 mm |

| Inch threads | 112 – 1/64 TPI |

| TAILSTOCK | |

| Quill diameter | 115 mm |

| Quill travel | 225 mm |

| Quill taper according to DIN 228 | MK 6 |

| Acceptance Accuracy | DIN 8605 |

Spindle bore on request: *165, 216 mm

The WEILER E-Series graphical user interface: simply smart!

Fast and simple communication between man and machine.

The smart user software developed by WEILER on the basis of the latest Siemens controller generation. It quickly and simply guides the operator to the finished workpiece – even without prior programming knowledge.

Three compelling arguments for your production:

- Machine simple workpieces in the same way as with a conventional machine – only more efficiently

- Machine elaborate workpieces in the same way as with a conventional machine – only faster

- Machine complex workpieces in the same way as with a CNC machine – only more simply

The advantages for you at a glance:

- Clearly structured interface

- 22” TFT screen with touch-sensitive membrane keyboard

- Manual turning

- Electronic turning against the stop

- Taper turning throughout the complete machining area

- Manual radius turning

- Simple cycles

- Smart cutting cycles with / without raw part contour

- Powerful geometry processor

- Grooving cycles / parting cycles

- Macros for undercuts

- Powerful thread cutting and drilling cycles

- Thread re-cutting cycle

- Cycles for driven tools

- DIN ISO programming

- DXF file import

- Tool memory for 300 tools

- Flow lists

- Simulation

- USB interface and network card

- Teleservice

Also available with Siemens ShopTurn control.

- Manual and automatic tool systems

- Holding brake for lathe spindle

- Pivoted C-axis

- Three and four jaw chucks

- Face plates

- Hydraulic clamping units

- Follower rests

- Fixed steady rests

- Boring block on the cross slide

- Custom machine enclosures

- Chip conveyor

etc.