SUSTAINABILITY AT WEILER

Sustainability affects the entire life cycle of a lathe and has been WEILER’s guiding principle for many years

Our understanding of sustainability is comprehensive: it covers the entire life cycle of a machine – from its planning and production to its operation and recycling.

- We already use powerful tools during the development and design of the precision lathes in order to conserve resources.

- We manufacture all precision lathes, including spare parts, in Germany at our Emskirchen site to conserve resources.

- In doing so, we rely on a high level of vertical integration and the purchase of local suppliers. Both have quality reasons – because this is how we can guarantee the quality and accuracy of our precision lathes.

- We also pay very close attention to the best possible solutions when purchasing components. This allows us to avoid cost-intensive and environmentally damaging parts tourism. Another advantage: short supply chains are resilient, which is why we were always able to deliver during the coronavirus pandemic. This is a positive side effect of our sustainability efforts.

WEILER lathes are sustainable in operation because

- they are particularly energy-efficient in everyday production,

- they are designed for maximum ease of set-up and maintenance,

- they are designed and built to be particularly solid and durable,

- We keep a long-term stock of spare parts that you can use reliably for decades to come,

- With the innovative “e-TIM” energy-saving system, the standby energy consumption of lathes can be significantly reduced.

Condition monitoring reduces wear and downtimes

Our condition monitoring system for predictive maintenance also ensures greater sustainability in the operation of precision lathes:

- The sensor-based mapping of the lathe and the documentation and analysis tools of the condition monitoring system help to detect failures caused by wear and collisions on lathes at an early stage and limit their effects.

- Service interventions and maintenance measures are therefore easier to predict. In this way, downtimes can be planned in advance, thus reducing costs.

- In addition, many maintenance tasks can be carried out more effectively. They do not have to be determined solely by the number of machine hours, as was previously the case, but can be calculated according to actual wear and tear.

Up to 85 per cent less energy thanks to “e-TIM“

With the help of our innovative “e-TIM” energy-saving system, the standby energy requirement of a large, powerful cycle lathe can be reduced by up to 85 per cent.

“E-TIM” is a triple intelligent energy-saving system:

- The drive management system permanently feeds the braking energy back into the power grid.

- Unnecessary auxiliary units are switched off automatically.

- When stationary, the machine switches to standby mode after a defined period of time.

Proven sustainability: modernisation and retrofitting instead of a new machine

It doesn’t always have to be a new lathe: There are more than just technical reasons for modernising or completely retrofitting a tried-and-tested machine – the environment also benefits.

Retrofit is resource-efficient and sustainable for many reasons:

- Lower energy consumption thanks to modern electric drives.

- All flawless components of a lathe are retained. No additional resources need to be used for them.

- Conversion of premises – as is sometimes necessary when purchasing new machines – is no longer necessary.

- Existing foundations can be used unchanged.

- Existing tools can still be used.

Further information on retrofitting lathes can be found on a separate page.

Sustainability in production: One third less CO2 emissions

WEILER is also committed to environmental protection in production: we generate electricity with a photovoltaic system on the roof of the assembly halls, and we feed the waste heat from a biogas plant into the heating network.

This is how much we have reduced CO2 emissions:

- in the company: -35 %

- in the vehicle fleet: -22 %

We have reduced the average amount of CO2 emitted per year by over 35% from 1,300 tonnes in 2005 to the equivalent of 840 tonnes in 2013. A significant proportion of this comes from more efficient heating (-31%) and photovoltaics (-4%).

Excellent sustainability

With the savings we have achieved, we are well above the industry average.

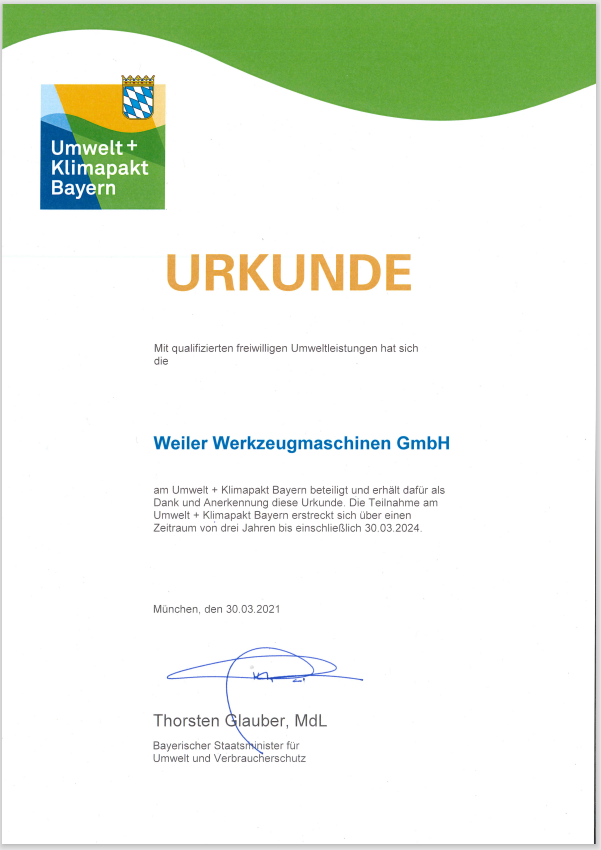

The Bavarian State Minister for the Environment and Consumer Protection has honoured us for our voluntary efforts to protect the environment and climate.

We are pleased to support the Bavarian Environmental and Climate Pact.

Voluntary commitment as a member of the Blue Competence Initiative

As a member of the VDMA initiative of the same name, WEILER has signed the sustainability code of the Blue Competence Initiative.

We are convinced that resource and cost efficiency are two sides of the same coin. Together with many other companies from the industry, we want to show within the Blue Competence Initiative that it is not only good but also useful to operate efficiently. For more sustainability in mechanical and plant engineering.

CERTIFICATE FOR ENVIRONMENTALLY FRIENDLY PRODUCTION

In the past, WEILER has repeatedly succeeded in reducing its energy requirements and thus also its CO2 emissions. For these and various other endeavours, we were also awarded a certificate by the Bavarian State Bavarian State Minister for the Environment and Consumer Protection.