CNC lathes from WEILER for production, training and research

CNC lathes from WEILER guarantee precision and efficiency in the machining of workpieces from a wide variety of materials – for more than forty years.

Users from industrial production, toolmaking, science and research institutes rely on CNC lathes from WEILER, as do those responsible for training, further education and training programmes.

Our modular lathes offer maximum flexibility and are equipped with the latest Siemens control technology. And all this in a small footprint.

The advantages of CNC lathes from WEILER:

- Solid construction:

All CNC lathes are characterised by their solid construction: Their heavy, vibration-resistant substructures rest on high-quality, heavily ribbed grey cast iron beds. - Small footprint:

The machines combine state-of-the-art technology in the smallest of spaces. They therefore only require a small footprint. They are the ideal choice for small rooms and confined working environments. - Excellent ergonomics and ease of operation:

Operators love WEILER CNC lathes because the workpiece is easily accessible from anywhere thanks to a generous sliding guard.

Access via a full PC keyboard and a swivelling control panel facilitate operation. - Versatile with the latest control system:

Thanks to their modular design and comprehensive range of additional equipment, CNC lathes from WEILER can be used for almost any machining task. The user-friendly WEILER user interfaces based on the latest Siemens control system simplify work. - Productive and efficient:

WEILER CNC lathes are characterised by particularly high precision, dynamics and reliability.

WEILER CNC lathes stand for precision

Our CNC lathes stand for unrivalled precision. They enable you to produce complex workpieces with the highest accuracy quickly and easily.

Six arguments in favour of special precision:

- Solid and rigid substructure

- Linear scale in the X-axis

- Highly dynamic linear guides

- Precise work spindle bearings

- High positioning accuracy

- High thermal stability

WEILER CNC lathes stand for enormous productivity

Short set-up times, highly dynamic drives and reliable operational safety guarantee the proverbial productivity that characterises our CNC lathes.

CNC lathes from WEILER: Short set-up times and high dynamics

- Short ramp-up times, therefore immediately ready for use

- Powerful axis and spindle drives

- High rapid traverse speeds

- Short turret swivelling times

- Rapid clamping pressure adjustment

This is why CNC lathes from WEILER are particularly reliable and safe to operate

- Lubricated-for-life working spindle

- Fully automatic centralised lubrication

Long maintenance intervals - Air/water-cooled spindle motor

- Electrically monitored safety clutches in all axes

- Tailstock can be moved in the programme via its own axis

- Rapid clamping pressure adjustment via pressure control valves with integrated pressure switch setting

- The latest WEILER One1 control system and ShopTurn user interface for universal usability and consistently high productivity

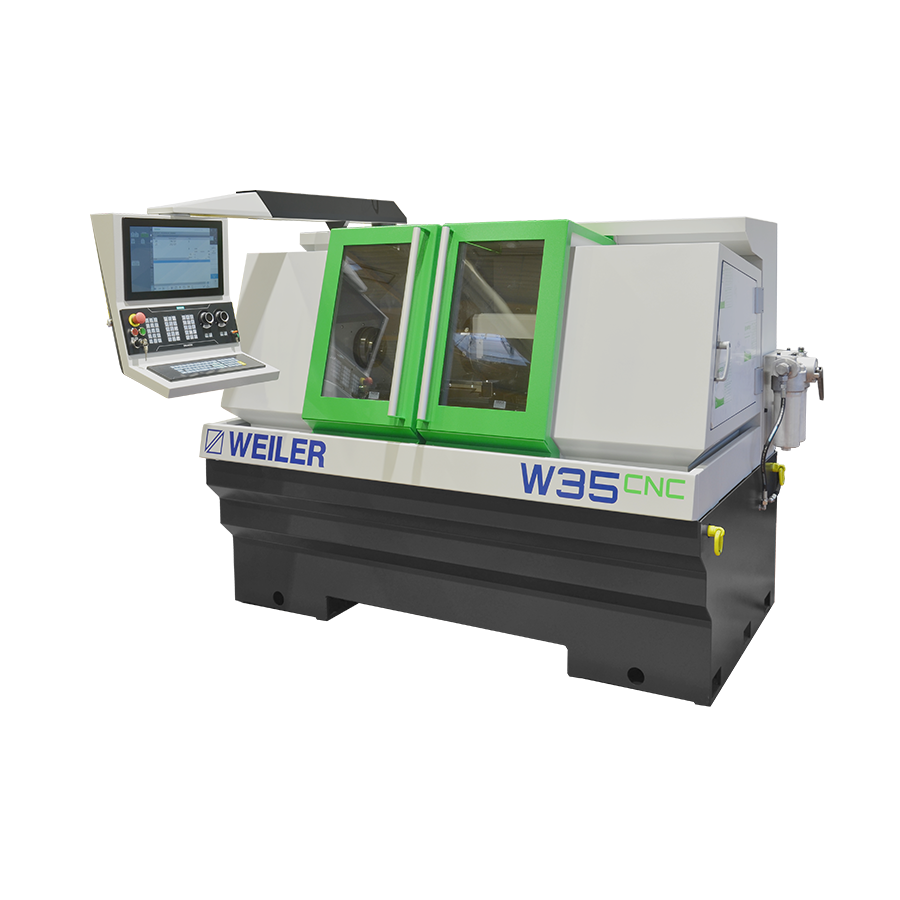

WEILER W 35 CNC: The future of CNC training

The W 35 CNC is a universal CNC precision lathe that WEILER has developed for training purposes. It is particularly compact, can be used for a wide range of applications and is equipped with the latest Siemens ONE1 control, ShopTurn user interface and a 19-inch touchscreen.

What characterises the WEILER W 35 CNC:

- It offers a maximum output of 9 kW, a torque of up to 90 Nm and a speed range of 1-4,500 rpm.

- With a centre width of 700 mm and a swing diameter over the bed of 360 mm, it is primarily used for the production of smaller components.

- We have designed them primarily for toolmaking, development and research as well as for training and further education in CNC turning.

- A wide range of accessories enables a variety of applications.

WEILER DZ 45: The CNC lathe for the highest demands

The DZ 45 CNC impresses with its accuracy and versatility. The CNC lathe guarantees the best concentricity, repeatability and transfer accuracy, making even the most demanding tasks easy to master.

It is the ideal choice for small spaces and confined working environments. With a tool turret for 16 driven tools and an additional Y-axis, it can fulfil a wide range of machining tasks.