WEILER education 4.0

WEILER EDUCATION4.0 – Training 4.0 on lathes

In cooperation with the Ansbach School of Mechanical Engineering and ZF Friedrichshafen AG at the Schweinfurt site, we have developed the EDUCATION4.0 digital learning platform for training on lathes.

The concept combines real and virtual learning content. It can be used in all training workshops, vocational schools, classrooms, lecture theatres – and directly on specially equipped “EDUCATION4.0” lathes.

All topics are harmonised and can be used by learners and teachers anytime and anywhere.

They can be worked on in different ways: Either on the large screen of a physical WEILER lathe or KUNZMANN milling machine specially configured for EDUCATION4.0 or via PC, tablet and smartphone on the virtual machine twin.

WEILER EDUCATION4.0

Training 4.0 on lathes

Interactive learning content

Training for everyone, anytime, anywhere

Machine accessories

GS certified accessories for training

Interactive learning content: Training for everyone, anytime, anywhere

All topics are prepared by WEILER in such a way that learners can engage with them interactively. They are available online on the MLS learning platform, which is supported by the VDMA and VDW Young Talent Foundation for Mechanical Engineering. Registered trainers, teachers, lecturers, trainees and other authorised persons can access them around the clock using any browser-based end device.

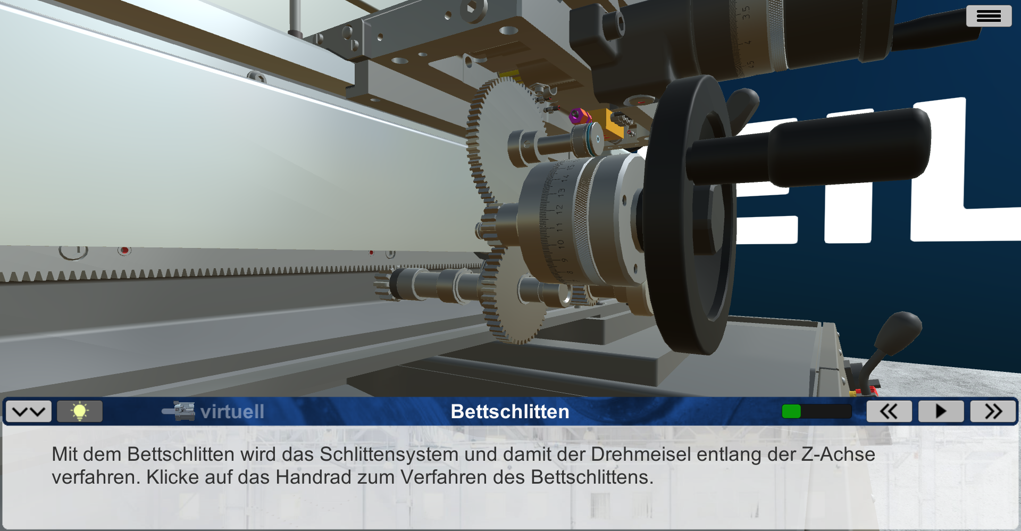

Varied interactive forms of learning

- animated tutorials

- 3D visualisations

- Machine instructions

- Videos on topics relevant to training

- exercises

- Tasks

Diverse learning content

All content developed by WEILER is stored centrally on the learning platform. In addition, every EDUCATION4.0 customer has the option of uploading formats they have developed themselves exclusively for their user group. Other users do not have access to this content.

Didactically prepared learning units are available on many topics:

- Machine basics

- Safety features

- Machine operation

- Machine functions

- Use of accessories

- Clamping devices

- Machine maintenance

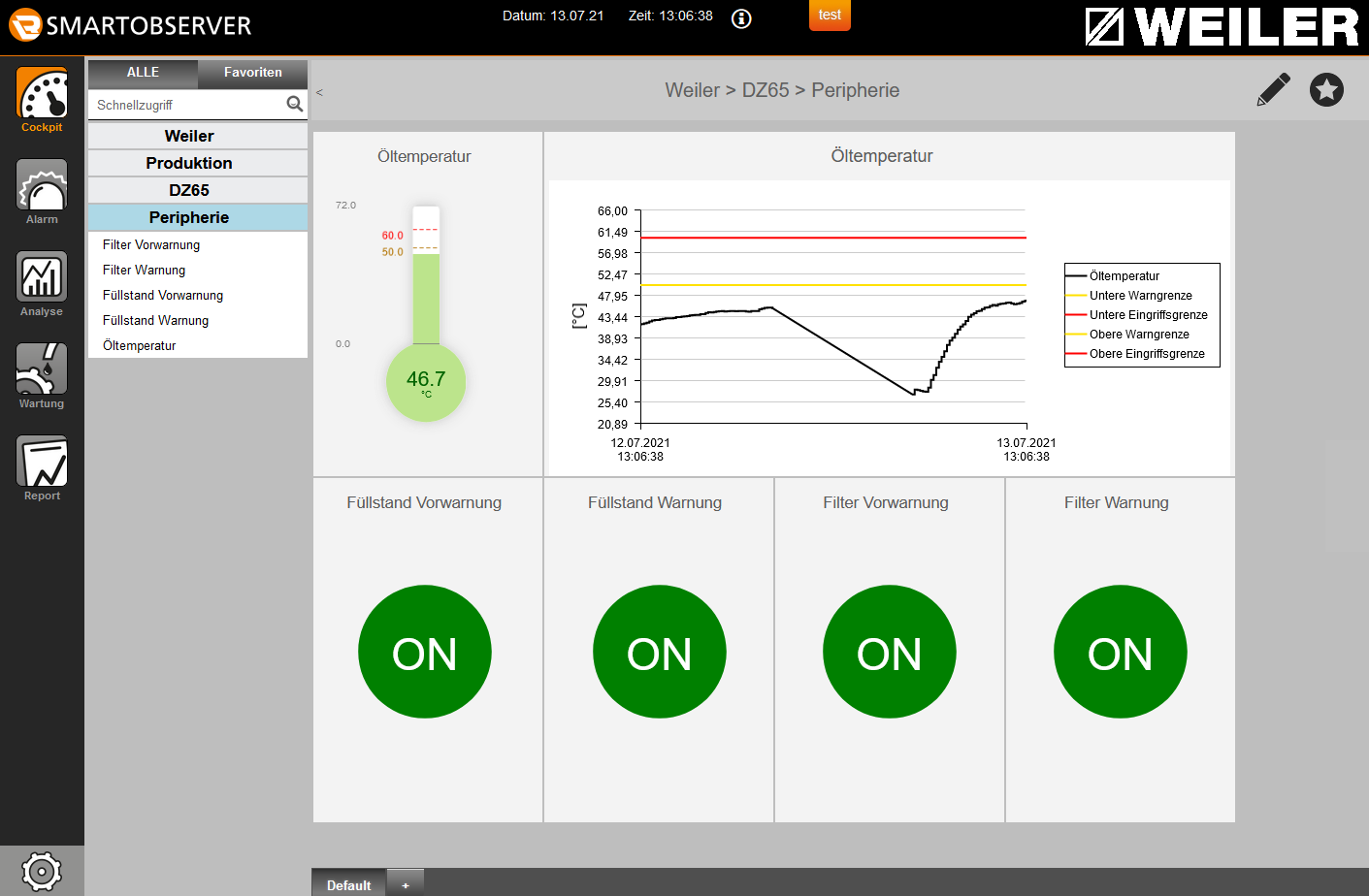

- Condition monitoring

- Networking of machines

EDUCATION4.0 promotes independent learning

If the trainee does not have a physical lathe at their disposal, they can learn independently on the machine’s digital twin instead.

This means that they can also work virtually and study content in exactly the way that is ideal for their level of knowledge, learning speed and learning behaviour.

Training4.0: Independent learning and distance learning

- Trainees can prepare for a new topic on their own.

- They can look at exercises at home that are due on the real lathe the next day.

- They can consolidate something they have already learnt.

- EDUCATION4.0 enables distance learning: teachers and trainers can use the learning platform to teach trainees tasks remotely, for example when lessons are cancelled.

What has been learnt is tested by tasks that have to be answered. Individual learning progress is saved in the user profile.

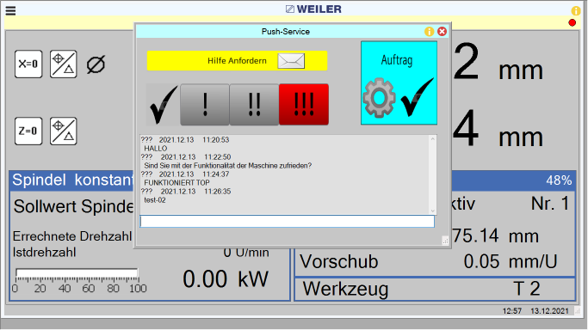

Communication via the learning platform

The cross-company communication between trainers, teachers and trainees is another advantage of the concept. With the help of the learning platform, everyone involved knows the individual level of knowledge of the trainees at all times.

The trainer can also issue different user authorisations depending on the individual learning progress: Only those who have successfully completed the corresponding tutorial are authorised to cut threads on the lathe.

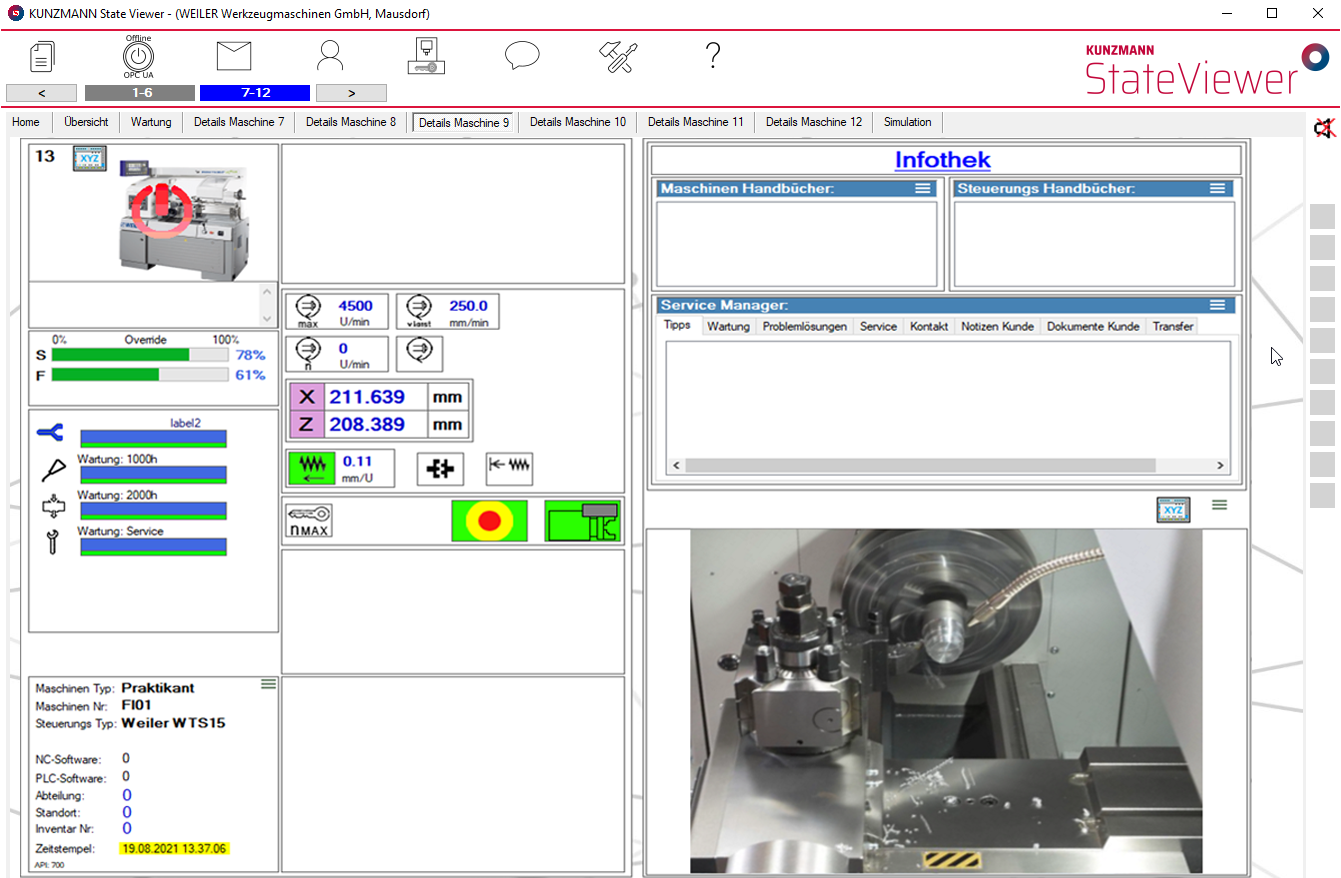

Digital dashboard StateViewer

Another component of training with the help of EDUCATION4.0 is the StateViewer. With this digital dashboard, a trainer can monitor machine parameters, view machine statuses and provide information centrally.

This allows him to see how his apprentices operate the machines, chat with them and provide them with information from his location.

Ideally prepared: Primus, Praktikant and Condor in the version „EDUCATION4.0“

The conventional Primus, Praktikant and Condor training lathes are available in the specially configured “EDUCATION4.0” version. With these models, you can utilise all the options offered by our digital learning concept right from the start.

EDUCATION4.0 is metal training for the digital age

The digital learning concept EDUCATION4.0 is the answer to two important questions relating to metal training:

- How can we get more people interested in training in a metal profession again?

- How can learning content in metal training be taught in a modern, attractive and interactive way?

As many young people who are willing to train lack access to technical topics, EDUCATION4.0 aims to appeal to young people by borrowing from the world of digital games.

EDUCATION4.0 is training 4.0

Our concept borrows from internet games and gaming software to develop target group-oriented and interactive learning content for individualised training on turning and milling machines.

Many funding opportunities for training via digital learning

There are numerous programmes, some of which offer extensive funding opportunities for digital learning. These include the Digital Pact for Schools and the ÜBS funding line for inter-company training centres. In addition, many federal states award further funding through their own programmes.

EDUACTION4.0 also for KUNZMANN milling machines

EDUACTION4.0 is also available for training on milling machines from our partner company KUNZMANN.

WEILER is the number 1 when it comes to lathe training

WEILER has been strongly committed to vocational training and further education for many years – far beyond EDUACTION4.0. Here you will find information on why WEILER is the number 1 in lathe training.