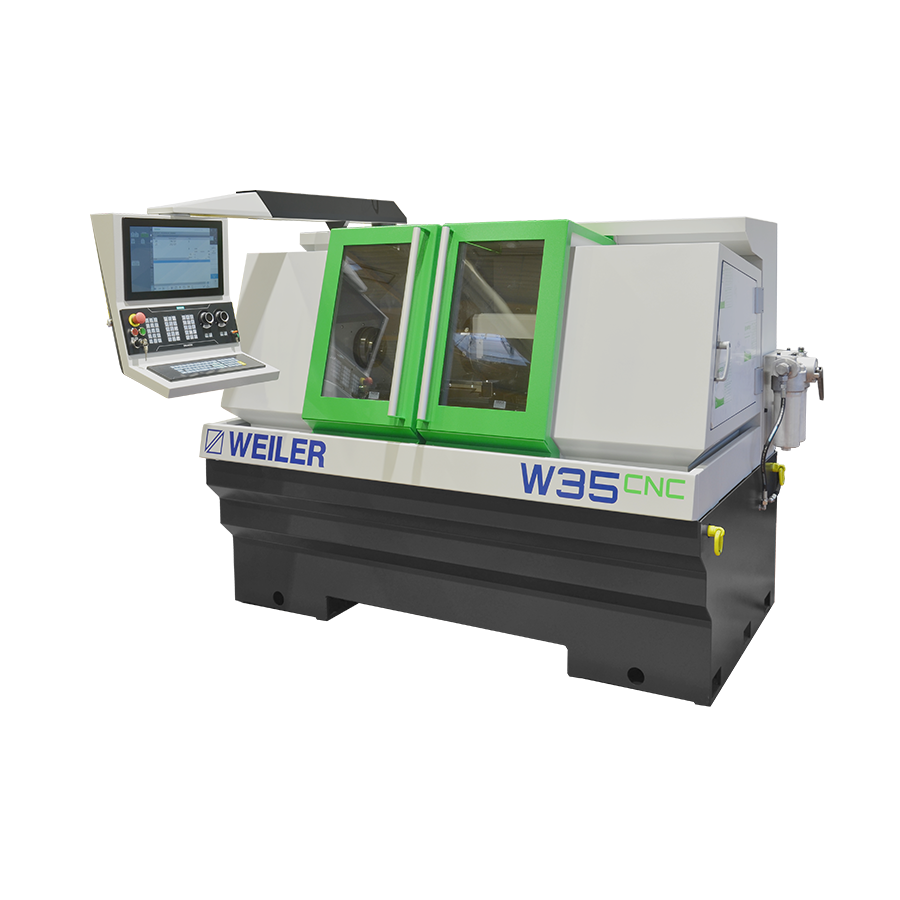

W 35 CNC

Thanks to its ergonomic design and generous workspace, the W35 CNC offers easy handling and short setup times.

The universal precision CNC lathe for toolmaking, institutes and forward-looking training and further education.

High-quality, energy-efficient, precise and universally applicable.

It convinces by:

- State-of-the-art control and drive technology

- easiest operability and programming

- highest accuracy

- long service life

- smallest space requirement

- and extensive range of accessories

- 19″ touch screen

Features

- 8 station disc turret with tool take-up DIN 69880 VDI20 mounted behind center line (with and without live tools).

- Center distance 700 mm

- Swing over bed 360 mm

- Full machine enclosure

- tailstock

- central lubrication

- Coolant system

- Broad speed range

- Extensive and practice-oriented accessories

- Data transfer via USB or network connection

- Multi-stage selectable energy control system (CTRL-ENERGY)

- LED work area lighting

- Machine accuracy according to DIN 8605

Technical Data

| W 35 CNC | W 35 CNC mit AGW | |

| WORKING RANGE | ||

| Centre heigh | 180 mm | 180 mm |

| Swing over bed | 360 mm | 360 mm |

| Swing over cross slide | 160 mm | 160 mm |

| Turning diameter | 220 mm | 190 mm |

| Distance between centres | 700 mm | 700 mm |

| LATHE SPINDLE | ||

| Spindle nose acc. to DIN 55027 (DIN ISO 702-3) | size 6 | size 6 |

| Spindle bore | 57 mm | 57 mm |

| Spindle diameter in front bearing | 90 mm | 90 mm |

| MAIN DRIVE | ||

| Drive power 60% / 100% duty cycle | 9/7 kW | 9/7 kW |

| Speed range | 1 – 4.500 rpm | 1 – 4.500 rpm |

| Max. torque of spindle | 90 Nm | 90 Nm |

| FEED RANGE | ||

| Feed force longitudinal | 0,001 – 10 mm/turn | 0,001 – 10 mm/turn |

| Feed force transverse | 0,001 – 10 mm/turn | 0,001 – 10 mm/turn |

| Feed force longitudinal | 7.000 N | 7.000 N |

| Feed force transverse | 3.000 N | 3.000 N |

| Max. Feed range longitudinal and transverse | 15/10 m/min | 15/10 m/min |

| THREAD CUTTING RANGE | ||

| Metric threads | 0,1 – 400 mm | 0,1 – 400 mm |

| Inch threads | 56 – 1/4 TPI | 56 – 1/4 TPI |

| TAILSTOCK | ||

| Quill diameter | 50 mm | 50 mm |

| Quill travel | 140 mm | 140 mm |

| Quill taper according to DIN 228 | MK 3 | MK 3 |

| TOOL TURRET | ||

| Tourelle à disque derrière le centre de tournage VDI20 | 8 | 8 |

| Cross section of turning tool (width x height) | 16 x 16 | 16 x 16 |

| Pitch diameter | 160 mm | 200 mm |

| Flight circle diameter | 320 mm | 350 mm |

| Powered tool stations | – | 8 |

| Speed at the tool drive | – | 4.000 rpm |

| ACCEPTANCE ACCURACY | DIN 8605 | DIN 8605 |

Control

Control of the CNC lathes by Siemens Sinumerik ONE

We at WEILER only use the best for our machines! The Sinumerik ONE control with the latest Siemens “Operate” user interface, including “ShopTurn”.

Together with our global partner Siemens, we guarantee high performance, reliability, ease of operation and maintenance.

With the Sinumerik control, you skillfully steer through the work process! And the high-resolution 19″ touch screen as well as the full keyboard support you in this.

Features:

- Modern text editor with many helpful functions

- Workshop-compatible technological cycles for turning, milling and drilling

- Residual material detection and machining for contour pockets and chip removal

- Powerful contour calculator for entering simple to complex contours

- Extensive work step programming with ShopTurn

- Fast checking of part programs

– Integrated 3D simulation for turning and milling - Recording of the current machining operation

– Real-time simulation of the current machining operation - Access to external programs via network drives and USB interfaces

- Support of the entire workflow

– Tool setup

– Set up, program, simulate and run in workpieces

– Monitoring machining

Accessories

- Three- and four-jaw manual chucks

- Power clamping devices

- Collet chuck devices

- Power operated tailstock quill

- D. back stop

- Oil mist extraction

- WEILER Condition Monitoring

ecc.

Downloads