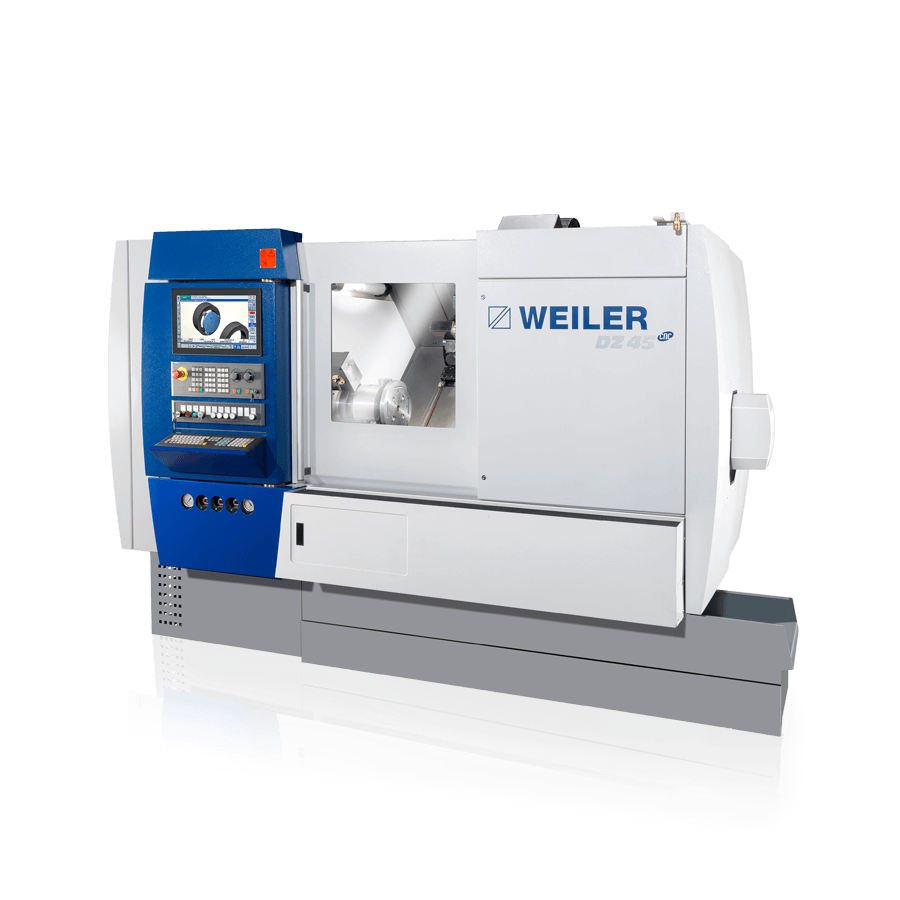

DZ 45

The ergonomic design ensures that the DZ45 CNC is particularly easy to use while offering very short setup times.

The CNC precision lathe for high productivity applications in production, tool making and research institutes as well as in apprenticeships and vocational training.

High quality, energy-efficient, precise and universally usable.

It impresses through:

- State-of-the-art control and drive technology

- Straight-forward operating and programming

- Extreme accuracy

- Durability

- User-friendly ergonomics

- Extremely small footprint

- and an extensive range of accessories and custom solutions

- Solid and compact machine construction

- Turning diameter 240 mm

- Turning length approx. 500 mm

- Bar capacity 42 mm

- Main drive with 21,5 kW

- Powerful axis drives

- Suitable for chuck, bar and shaft operations

- Y-axis for machining complex workpieces

- Sub-spindle

- Up to 16 driven tools

- Complete machining of workpieces without re-setting

- High rapid traverse speeds

- High accuracy through direct path measuring system

- Wide variety of possible applications

- Integrated safety function for all axes (safety integrated)

- LED machine lights

| AR | ARY | AGY | |

| WORKING RANGE | |||

| Turning diameter, max. | 240 mm | 240 mm | 240 mm |

| Z-axis travel | 530 mm | 525 mm | 525 mm |

| X-axis travel | 207,5 mm | 220 mm | 207,5 mm |

| MAIN DRIVE – VERSION | |||

| Speed range | 6.000 min-1 | 6.000 min-1 | 6.000 min-1 |

| Drive power 60 % duty cycle | 21,5 kW | 21,5 kW | 21,5 kW |

| Torque at main spindle 60 % duty cycle | 128 Nm | 128 Nm | 128 Nm |

| MAIN SPINDLE | |||

| Spindle nose according to DIN 55026 (DIN ISO 702-1) | size 5 | size 5 | size 5 |

| Chuck diameter | 160 mm | 160 mm | 160 mm |

| Bar capacity in draw/thrust tube, sub-spindle | 42 mm | 42 mm | 42 mm |

| FEED DRIVE | |||

| Feed force X/Z/Q | 412 daN | 412 daN | 412 daN |

| Rapid traverse X/Z/Q | 30/30/30 m/mm | 30/30/30 m/mm | 30/30/30 m/mm |

| TAILSTOCK | |||

| Centre fixture | 4 MK | 4 MK | – |

| Supporting force, max. | 530 daN | 530 daN | – |

| SUB-SPINDLE-VERSION | |||

| Spindle nose according to DIN 55026 (DIN ISO 702-1) | – | – | size 5 |

| Chuck diameter | – | – | 160 mm |

| Bar capacity in draw/thrust tube, sub-spindle | – | – | 42 mm |

| Sub-spindle speed range | – | – | 6.000 min-1 |

| Sub-spindle drive power60 % duty cycle | – | – | 17 kW |

| Torque at 60 % duty cycle | – | – | 80 Nm |

| TOOL TURRET | |||

| Number of tool stations, not live/live | 12/12 | 16/16 | 16/16 |

| Shank diameter according to DIN 69880 | 30 mm | 25 mm | 25 mm |

| Tool shank cross section | 20×20 mm | 16×16 mm | 16×16 mm |

| Drive power at 100 % duty cycle | 4,5 kW | 5,2 kW | 5,2 kW |

| TOOL TURRET WITH Y-AXIS | |||

| Y-axis travel | – | + 45/- 35 | + 45/- 35 |

| Controller | 840 D Sinumerik | 840 D Sinumerik | 840 D Sinumerik |

These CNC lathes are controlled by Siemens Sinumerik 840D sl controllers

With Siemens you are sure to have everything under control.

At WEILER only the best is good enough for our machines. Sinumerik 840D sl controllers feature the latest Siemens “Operate” graphical user interface.

With the global player Siemens as our partner, we guarantee high performance and reliability together with ease of operation and maintenance.

Sinumerik controllers enable you to expertly control your complete machining process! A high-resolution 19” LED touch screen and a full-scale keyboard assist you in the process.

Features:

- Latest text editor with a wide variety of useful features

- Workshop-oriented technological cycles for turning, milling and drilling

- Recognition of residual material and processing for contour pockets and cutting

- Powerful contour calculator for the input of the simplest to the most complex contours

- Extensive working step programming with ShopTurn

- Rapid inspection of part programs

– Integral 2D simulation for turning and milling, 3D simulation - Simultaneous recording of the current machining operation

– Real-time simulation of the machining - Access to external programs through network drives, USB and COM interfaces

- Assistance throughout the complete machining process

– Tool setup

– Workpiece setup, programming, simulation and feeding

– Machining process monitoring

- Various tool turrets

- NC tailstock

- Sub-spindle

- Hydraulic power chuck

- Hydraulic collet systems

- Workpiece pick-up device

- Conveyor

- Spring ejector

- Chip conveyor

- Optical tool calibration

- Oil mist exhaust system

etc.