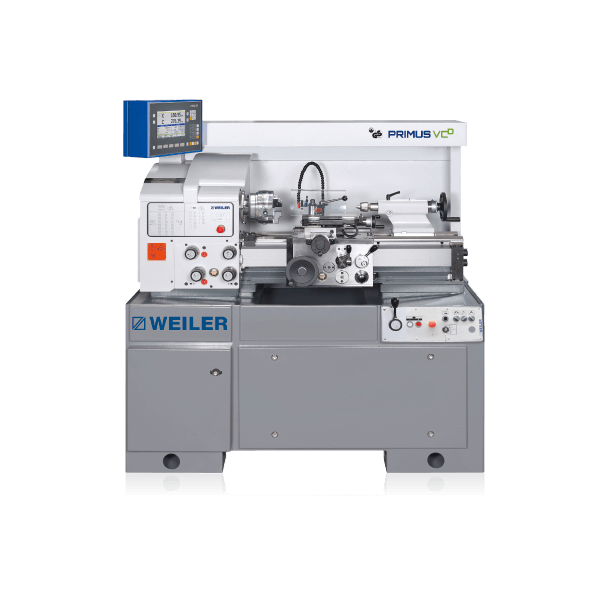

Primus VCD

WEILER’s best-selling machine for high level training combines quality and versatility with straight-forward operation for all users. In common with all WEILER machines, risks during operation are minimised by taking all relevant safety aspects into account.

The smallest WEILER precision engine lathe is characterised by:

- Sophisticated technology

- Extreme accuracy

- Durability

- Field-proven ergonomics

- Extremely small footprint

- and an extensive range of accessories

Successfully used for decades in one-off and small-batch production, craft workshops and industry, apprenticeships and vocational training, in tool making and jig manufacture.

Features

- Distance between centres 500 mm

- Centre height 140 mm

- Automatic handwheel release

- Lead screw and feed rod cover

- Holding brake

- Toolmakers accuracy in accordance with DIN 8605

- Infinitely variable speed control with maintenance-free three-phase asynchronous motor

- Speed regulated frequency converter with actual value feedback

- The speed can be infinitely and precisely optimised during machining

- Optimum cutting conditions for fast machining of extremely fine surface structures

- The numerical read-out VCD (option) offers a high level of operating convenience for working with constant cutting speed, freely selectable speed limitation, oriented main spindle stop

- LED machine lights

Technical Data

| Working Range | |

| Centre height | 140 mm |

| Swing over bed | 280 mm |

| Swing over cross slide | 150 mm |

| Distance between centres | 500 mm |

| LATHE SPINDLE | |

| Spindle nose acc. to DIN 55027 (DIN ISO 702-3) | size 5 |

| Spindle bore | 43 mm |

| Spindle diameter in front bearing | 70 mm |

| MAIN DRIVE | |

| Spindle nose acc. to DIN 55027 (DIN ISO 702-3) | – / 4 kW |

| Spindle bore | 30 – 4.000 (5.000) rpm |

| Number of speeds | stufenlos |

| FEED RANGE | |

| Number of feeds | 24 |

| Longitudinal | 0,02 – 0,63 mm/turn |

| Transverse | 0,006 – 0,2 mm/turn |

| THREAD CUTTING RANGE | |

| Metric threads | 0,25 – 8* mm |

| TAILSTOCK | |

| Quill diameter | 40 mm |

| Quill travel | 85 mm |

| Quill taper according to DIN 228 | MK 3 |

| Acceptance Accuracy | DIN 8605 |

* inch threads and metric threads (0.45; 0.75; 4.5 and 5.5) are only feasible using additional change gears

Display

WEILER Digital Readout with screen for VCD machines with constant cutting speed (V-constant)

- 3-axis display for bed, cross and top slides

- Direct speed input and readout

- Constant cutting speed

- Freely selectable speed limit (lockable via key switch)

- Oriented spindle stop

- Tool technology memory for 99 tools

- Power display in percent (graphical) and kW

- Switching off the axis displays using a key switch (for training purposes)

Accessories

- Tool systems

- Three and four jaw chucks

- Face plates

- Collet devices

- Hollow spindle stops

- Follower rests

- Fixed steady rests

- Coolant equipment

- Moving chip and splash guards

- Digital readouts

etc.

Downloads

Primus VCD

Primus VCD

Primus VCPlus

Primus VCPlus

Praktikant GSD

Praktikant GSD

Praktikant VCD

Praktikant VCD

Praktikant VCPlus

Praktikant VCPlus

Condor VCPlus

Condor VCPlus

Commodor 180 GSD

Commodor 180 GSD

Commodor 180 VCD

Commodor 180 VCD

Commodor 230 VCD

Commodor 230 VCD

DA 210

DA 210

DA 260

DA 260

DA 210 AC

DA 210 AC