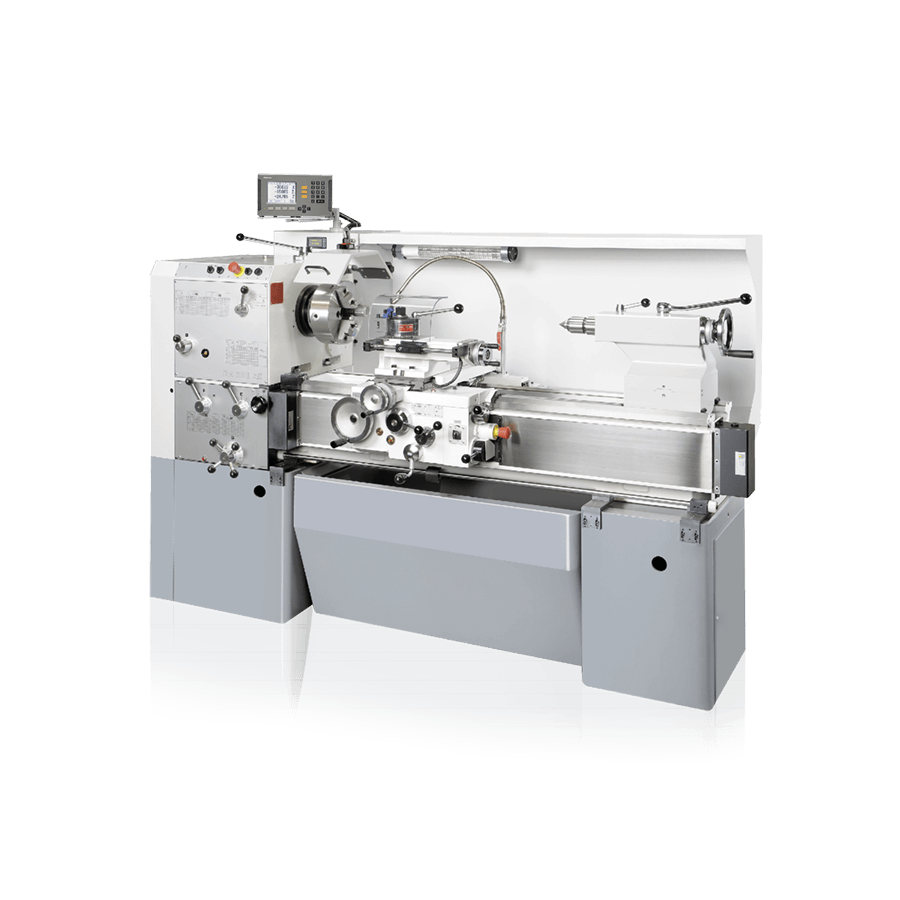

Features

- Centre height 210 mm

- Distance between centres 1000 mm or 1500 mm

- Lead screw and feed rod cover

- Brake for main spindle

- Toolmakers accuracy in accordance with DIN 8605

- High power output and high torque at the main spindle

- Frequency converter and speed potentiometer for stepless speed control

- Digital speed indicator

- Large thread cutting range

- Easy operation

- Digital readout (option)

- LED machine lights

Technical Data

| WORKING RANGE | |

| Centre height | 210 mm |

| Swing over bed | 435 mm |

| Swing over cross slide | 245 mm |

| Distance between centres | 1.000/1.500 mm |

| LATHE SPINDLE | |

| Spindle nose acc. to DIN 55027 (DIN ISO 702-3) | size 6 |

| Spindle bore | 52 mm |

| Spindle diameter in front bearing | 83 mm |

| MAIN DRIVE | |

| Drive power 60% / 100% duty cycle | – / 10,5 kW |

| Speed range | 20–2.500 rpm |

| Number of speeds | stepless |

| FEED RANGE | |

| Number of feeds | 55 |

| Longitudinal | 0,072 – 2 mm/turn |

| Transverse | 0,036 – 1 mm/turn |

| THREAD CUTTING RANGE | |

| Metric threads | 0,5 – 14 mm |

| TAILSTOCK | |

| Quill diameter | 65 mm |

| Quill travel | 120 mm |

| Quill taper according to DIN 228 | MK 4 |

| Acceptance Accuracy | DIN 8605 |

* Inch threads and metric thread pitches 0.45; 0.75; 4.5 and 5.5 are only possible with additional change gears

Display

The Heidenhain ND 780 Position Display Unit

- 3-axis display for bed, cross and top slides

- Tool memory for 16 tools Tool memory with a datum for each axis

- Sum key for Z und Zo

- Switchable between inch and metric

- X cross travel as radius or diameter display

- Delta key “distance to go to zero“

- Resolution up to 1 µ

- “Hold“ the actual position

- Taper calculator

Accessories

- Tool systems

- Three and four jaw chucks

- Face plates

- Collet devices

- Hollow spindle stops

- Follower rests

- Fixed steady rests

- Coolant equipment

- Moving chip and splash guards

- Digital readouts

etc.

Downloads

Primus VCD

Primus VCD

Primus VCPlus

Primus VCPlus

Praktikant GSD

Praktikant GSD

Praktikant VCD

Praktikant VCD

Praktikant VCPlus

Praktikant VCPlus

Condor VCPlus

Condor VCPlus

Commodor 180 GSD

Commodor 180 GSD

Commodor 180 VCD

Commodor 180 VCD

Commodor 230 VCD

Commodor 230 VCD

DA 210

DA 210

DA 260

DA 260

DA 210 AC

DA 210 AC